Simatic Step 5 Software Crack

Found 8131 results for: Crack Simatic Step 5. Crack download software DATAM COPRA RF v2009 Rocscience Phase2 v9.015 Green Mountain mesa v14 fracman v7.5.1 Ctech EVS MVS EVS-PRO v9.94. SIMATIC STEP 7 Basic (TIA Portal) is a price-optimized subset of STEP 7 Professional controller software in the TIA Portal that can be used for engineering SIMATIC S7. Listing of free/demo PLC software available online. All known restrictions are listed. Windows ME y Windows 2. 2 sobre Windows XP.

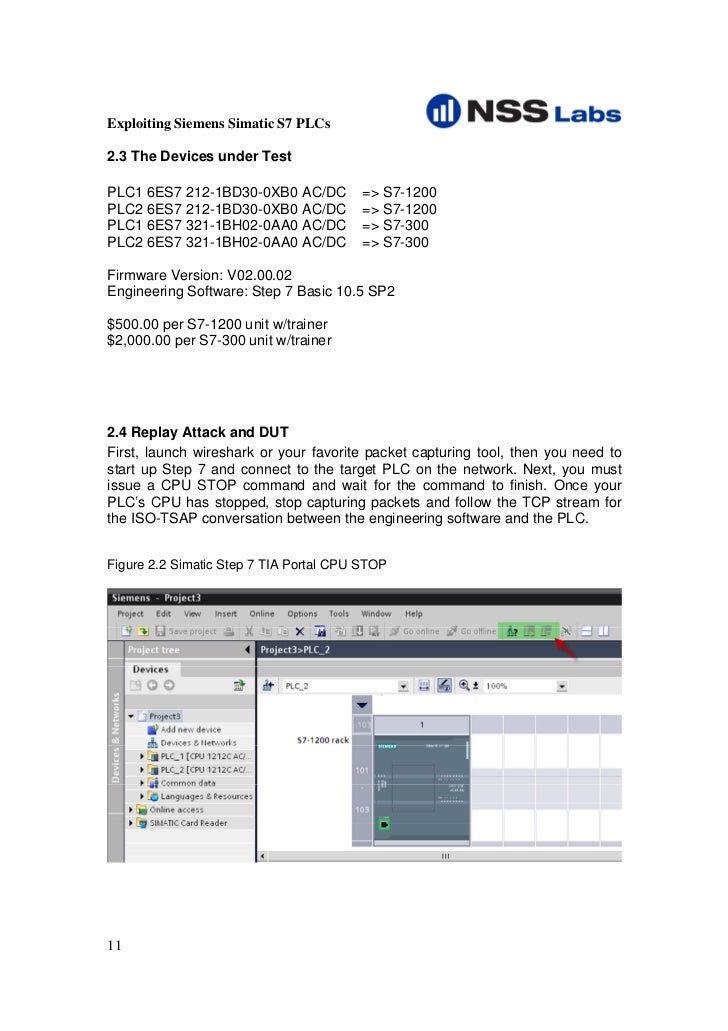

ScreenShots:

Software Description:

Siemens SIMATIC STEP 7 software is theprofessional tool for the SIMATIC S7, SIMATIC C7 and SIMATIC WinACautomation systems. It enables the user to use the performancecapability of these systems easily and conveniently.

SIMATIC STEP 7 contains convenient functions for all phases of anautomation project:

– Configuring and parameterizing the hardware

– Specifying the communication

– Programming

– Test, start-up and service

– Documentation, archiving

– Operating/diagnostics functions

SIMATIC STEP 7 program tools:

1. SIMATIC-Manager:

The SIMATIC Manager manages all data belonging to an automationproject, regardless of the target system (SIMATIC S7, SIMATIC C7 orSIMATIC WinAC) on which they are implemented.

It provides a common entry point for all SIMATIC S7, C7 or WinACtools. The SIMATIC software tools that are necessary for processingthe selected data are automatically started by SIMATIC Manager.

2. Symbol-Editor:

With the tool Symbol Editor all global variables (in contrast tothe local formal parameters that are declared when the blocks areprogrammed) are managed. The following functions are available:

– Definition of symbolic designations and comments for the processsignals (inputs/outputs), flags and blocks

– Sorting functions

– Data exchange with other Windows programs

The symbol charts that are generated when this tool is used areavailable to all software products. Changes to a symbol parameterare therefore automatically recognized by all tools.

3. Hardware configuration:

The tool Hardware Configuration is used for configuring andparameterizing the hardware used for an automation project. Thefollowing functions are available:

– Configuration of the automation system Racks are selectedfrom an electronic catalog and the selected modules are assigned tothe required slots in the racks.

– The configuration of the distributed I/Os is done in the same wayas the configuration of the non-distributed I/Os; channel-granularI/O modules are also supported.

– CPU parameter assignment:

Properties such as restart characteristics and cycle-timemonitoring can be set menu-driven. multicomputing is supported. Theentered data are filed in system data blocks in the CPU.

– Module parameter assignment:

The user can specify all the adjustable parameters of the modulesin input screen forms. Adjustments via DIP switches becomeunnecessary. Parameterization of hardware modules occursautomatically during the CPU’s acceleration. Thus, a change of amodule can be made without another parameterization.

– Function module (FM) and communications processor (CP) parameterassignment:

This parameterization also occurs within the hardware configurationin the same way as the parameterization of the other modules. Forthis parameterization hardware-module-specific screen forms andrules are provided for each FM and CP (is included in the FM/CPfunctions package). The system prevents faulty inputs by offeringonly allowed entry options on the parameter assignment screenforms.

4. Communication configuration:

– Configuring and display of communication links

– Time-driven cyclic data transmission via MPI:

– Selection of communication partners

– Entering of data source and data destinationin a table.Generation of all system data blocks (SDBs) to be loadedand their complete transmission to all CPUs take placeautomatically

– Parameterization of the selected communicationblocks in the customary programming language (e.g., LAD).

– Event-driven data transmission

– Definition of the communication links.

– Selection of the communication function blocks (CFBs) from theintegrated block library.

– Parameterization of the selected communication blocks in thecustomary programming

language (e.g., LAD).

5. System diagnostics:

System diagnostics offer the user an overview of the status of theautomation system. The display can be in two different forms:

– Display of text messages, which can be output directly andquickly.

– Pixel-graphics display within the Hardware Config display,offering the following options:

– Display of general module information (e.g., order number,version, designation) and module status (e.g., faulty)

– Display of module faults (e.g., channel faults) of thecentral I/O and DP slaves

– Display of alarms from the diagnostics buffer

For CPUs, additional information is displayed:

– Causes of malfunction during user program execution.

– Display of cycle duration (longest, shortest and last cycle).

– Display of the reserved and free memory.

– Capabilities and usage of MPI communication.

– Display of the performance data (number of possibleinputs/outputs, flags, counters, timers and blocks)

Installer Size: 2889 MB

Download Links : Siemens SIMATIC STEP 7 Professional 2017 (STEP 7 v5.6 + S7-PLCSIM v5.4 SP8 + S7-SCL v5.6 + S7-GRAPH v5.6 + S7-PCT v3.4 HF2) x64 + Crack

SIMATIC WinCC is a powerful product of German company Siemens for monitoring and analyzing industrial automation. In fact, this software is in SCADA’s “Supervisory Control and Data Acquisition” software group in Persian system of data management and data collection or SCADA Placed. For example, SCADA in a factory is responsible for displaying, controlling and monitoring the complete production line of the plant. Of course, the Siemens Simatic WinCC software has been developed to work with PLCs. With this software, you will have full control over the system functions visually in Windows, no matter whether you are faced with a single-user system or multi-user systems distributed over the network platform of the servers, however, this program Designed for this purpose. WinCC is a modern, user-friendly interface for work in the world of industrial automation, an efficient and reliable application, offers an ideal configuration and, given its excellent scalability, ranges from simple systems to tasks in complex systems. Covering, in one word, Simatic WinCC is responsible for clarifying the production process.

Features and Features of SIMATIC WinCC:

- Beautiful and simple user interface

- High performance in data handling and proper analysis

- Appropriate scalability

- Various visualization process packages

- Reporting and recording performance reports

- Ability to script with VB Script for enhanced functionality

- Management Tools and Services for Troubleshooting, Management, and Remote Monitoring (Internet and Email Communications)

- A separate configuration and design environment and direct communication between these two environments

- Preview the pages in WinCC Explorer

- Display analog alarms in the TrendControl section

- System logins during logon and logon

Installation guide:

Install the software and click on Skip at the end of the installation and window view of the License; From the Windows settings, enable hidden files and system, and then delete the files in the AX NF ZZ folder located at the root of the C drive.

Related Posts:

Run the Slim_EKB_Install … file in the [email protected] folder and select the required permissions in the list and click the Install button.

Run the Automation License Manager tool and select the License keys menu item and then select Drive C. Now, with Ctrl + A, select all installed privileges, and then right-click on Check.

To view the list of activated software and the list of software required to activate, select the Licensed software options and Missing license keys respectively from the menu dropdown bar.

If there is software in the Missing license keys list, you should find and install it in the list in the licensing tool Slim_EKB_Install.

Installed educational video is also available.

With this method installed on Windows 7 on January 7, 2009, the 64-bit version was installed and successfully activated.

Siemens Simatic Software Download

Screenshot image

Direct links download:

Siemens Simatic WinCC v7.5 x64

Siemens Simatic S7 Software

Siemens SIMATIC WinCC 7.4

Siemens SIMATIC WinCC 7.4 SP1 Update Only

Siemens SIMATIC WinCC Flexible 2008 SP5

View file password here